Welcome to Mulan manufacture Group .

Mulan manufacturing group is a professional manufacturer of metal parts, Customer plastic molding/injection mould making, metal casting, metal fabrication, sheet metal fabrication, metal stamping and CNC precision machining in China. We focus on custom manufacturing, We have 7 professional engineers,in charge of plastic mold/injection mould, metal casting metal stamping etc.Professional analysis and evaluation of your products. We have 5 professional Quality control engineers, 10 English sales manager, We can serve 7*24 hours. Be professional with your products.

Mulan manufacturing group is a professional manufacturer of metal parts, Customer plastic molding/injection mould making, metal casting, metal fabrication, sheet metal fabrication, metal stamping and CNC precision machining in China. We focus on custom manufacturing, We have 7 professional engineers,in charge of plastic mold/injection mould, metal casting metal stamping etc.Professional analysis and evaluation of your products. We have 5 professional Quality control engineers, 10 English sales manager, We can serve 7*24 hours. Be professional with your products.

Mulan's Precision CNC flame cutting service .

The principle of flame cutting is that the combustible gas heats the steel to the "burning point" temperature (about 1800F), preheats it to the temperature, and then sprays pure oxygen into the hot steel to produce an exothermic reaction, eroding the steel.

The principle of flame cutting is that the combustible gas heats the steel to the "burning point" temperature (about 1800F), preheats it to the temperature, and then sprays pure oxygen into the hot steel to produce an exothermic reaction, eroding the steel.

Flame cutting can only cut carbon steel, 6mm- 150mm thickness.The cutting speed is faster than other processes when the thickness is over (about 50mm).Low cost, double capacity. The drawback is that this method is only suitable for cutting carbon steel, and flame cutting is not suitable for other types of metals, such as stainless steel and aluminum.

Productivity: flame cutting is low in efficiency due to long preheating time and slow cutting speed.

Productivity: flame cutting is low in efficiency due to long preheating time and slow cutting speed.

Precision of cutting parts: under the most suitable speed, height, gas and nozzle, the size tolerance of cutting parts is probably plus or minus 0.030 "(about 0.76mm), and the slope is less than 1 degree, but it must exist.

Edge quality, metallurgy performance: rough section and slag.

Maintenance: every year, Mulan entrusts the machine to the supplier for maintenance inspection.

Plasma cutting is the use of hot ionized gas to generate high energy density of cutting arc, so can cut all conductive materials.Fine plasma is most suitable for cutting carbon steel between 0.5mm and 50mm thick, as well as stainless steel and aluminum within 160mm thick.

Plasma cutting is the use of hot ionized gas to generate high energy density of cutting arc, so can cut all conductive materials.Fine plasma is most suitable for cutting carbon steel between 0.5mm and 50mm thick, as well as stainless steel and aluminum within 160mm thick.  Precision of cutting parts: the size tolerance of carbon steel cutting parts is about 0.38mm to 0.0.5 mm.Sheet with thickness less than 9.5mm and slope at 2-3 degrees.For thick plates with thickness greater than 12.7mm, the slope is within 1 degree.

Precision of cutting parts: the size tolerance of carbon steel cutting parts is about 0.38mm to 0.0.5 mm.Sheet with thickness less than 9.5mm and slope at 2-3 degrees.For thick plates with thickness greater than 12.7mm, the slope is within 1 degree.

Mulan's Precision CNC laser cutting service.

Laser cutting, by focusing, melts the material being cut, and the auxiliary gas (usually oxygen used to cut carbon steel) blows away the molten metal.Lasers are commonly used for precision cutting or efficient cutting of very thin steel plates.Lasers can cut metals more than an inch thick, but a more powerful laser is needed.

Laser cutting, by focusing, melts the material being cut, and the auxiliary gas (usually oxygen used to cut carbon steel) blows away the molten metal.Lasers are commonly used for precision cutting or efficient cutting of very thin steel plates.Lasers can cut metals more than an inch thick, but a more powerful laser is needed.

Productivity: highest productivity on a sheet.

Productivity: highest productivity on a sheet.

Precision of cutting parts: the size tolerance of laser cutting parts is about 0.5mm.Better than plasma, with a gradient of less than 1 degree.

Maintenance requirements: supplier shall inspect and maintain the equipment annually

Therefore, the production of parts needs to consider product requirements and assembly functions. Mulan has rich experience in metal cutting and can produce qualified products in the most efficient way.Send your product 3D design model, and we will reply to you within 24 hours.

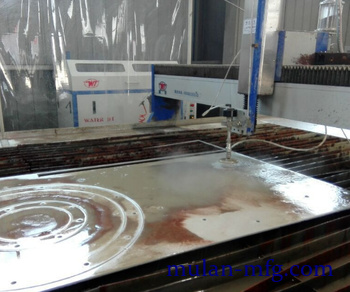

Mulan 's CNC water cutting service .

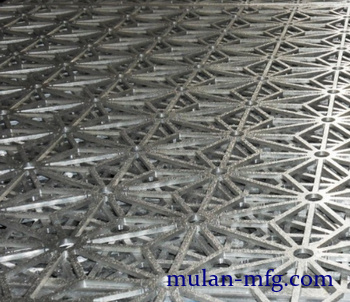

Water cutting, also known as water knife, is a high pressure water jet cutting technology, is a high pressure water cutting machine.Under the control of the computer can be arbitrary work, and material quality is less affected.Because of its low cost, easy operation and high yield, water cutting is becoming the mainstream cutting method in industrial cutting technology.

Water cutting, also known as water knife, is a high pressure water jet cutting technology, is a high pressure water cutting machine.Under the control of the computer can be arbitrary work, and material quality is less affected.Because of its low cost, easy operation and high yield, water cutting is becoming the mainstream cutting method in industrial cutting technology.

Material range: such as stainless steel, aluminum, copper, steel, marble, alloy metal, glass, plastic, ceramics, tiles and various materials available.

Accuracy is between 0.1mm and 0.25mm

1. A wide range of cutting materials

1. A wide range of cutting materials

2. Good cutting quality

3. No thermal processing

4. Environmental protection

5. No need to replace the cutter

Reduce burrs

7. Rapid programming

8. Various cutting shapes can be completed

9. No secondary processing is required, which can save time and manufacturing cost

Mulan's EDM wire cutting service .

Edm wire cutting is referred to as "wire cutting".It adopts electrode wire (molybdenum wire, tungsten-molybdenum wire, etc.) as tool electrode. Under the action of pulse power source, spark discharge is formed between tool electrode and workpiece, and a large amount of heat is generated in the spark channel instantly, so that the workpiece surface is melted or even vaporized.The wire cutting machine moves the electrode wire along the predetermined trajectory through XY plate and UV plate.

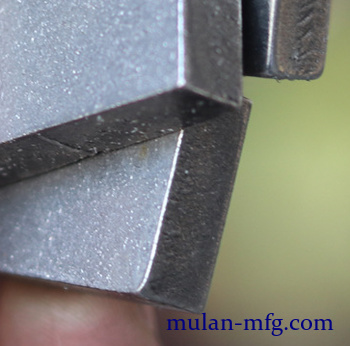

The machining accuracy of wire cutting can reach + / - 0.01mm, surface roughness R = 1.25 ~ 2.5um.Linear cutting can be used to process hard alloy or hard metal workpieces with high hardness and complex profile, such as quenching, etc

1. The little deformation

2. Low cutting loss

3. It is very suitable for processing complex parts, single parts and trial products in small batches with short processing cycle.

4. Four-axis linkage can be used to produce tapered, upper and lower parts.

5. High precision

Mulan's Precision CNC laser cutting products.

Mulan 's CNC water cutting products.

Mulan's Edm wire cutting products.

Mulan can do a lot.

We provide one-stop service. If your product requires the cooperation of multiple devices, mulan is your best choice.We can use different equipment to produce your products, and we can also carry out subsequent surface processing, such as spraying plastic polishing, sandblasting, anodizing, electrolytic polishing.

If you need cutting products,

Please contact us. Click : contact@mulan-mfg.com

1 Day

Mulan's service is 7*24 hours. When we receive your product requirements, we will reply to you within 5 hours. You may receive a greeting from us, but we may have made a simple assessment of your requirements.If you are on the other side of the earth, please forgive us for replying to you within 24 hours.

If your design is simple and you can tell us all the requirements, then we can start production in 2 hours.Mulan has its own processing plant, more than 10 years of precision car processing experience, complete tools, professional production.

If your products are in small quantities, not special materials, then we can finish your production within 7 days and start the final quality inspection.

Mullan's quality inspection team is an engineer who has been working in the precision vehicle processing industry for over 20 years, with CMM and enough inspection tools to help.

It will take at least one month to ship goods from China to your country, which is a time that mulan cannot save. However, mulan has a professional international shipping logistics team, which can save the time of handling international shipping documents. Therefore, you can submit all your requirements to Mulan.

After 10 years of development,

Mulan has integrated more than 30 manufacturing processes,

We are your one-stop supplier.

Mulan’s Products and Services:

1. Metal Casting: Die Casting, Sand Casting, Gravity Casting, Investment Casting, metal forging and low pressure casting

2. Metalworking Service: Metal Fabrication, Sheet Metal Fabrication, Structural Metal Fabrication, Metal Frame Manufacturing, Welding Service, Cutting Service, Metal Bending, Plate Rolling, Metal Roll Forming, Sheet Folding, Metal Stamping, Deep Drawn Stamping, Expanded Sheet Metal and Metal Perforating.

3. Precision Machining Service: CNC Turning, CNC Milling, CNC Drilling, CNC Boring, CNC Grinding, CNC Cutting, Laser Engraving and Laser Marking.

4. Plastic Molding: Injection Molding, Rotational Molding, Blow Molding, Vacuum Forming and Thermoforming.

5. EDM Machining Service: Wire EDM Machining, Sinker EDM Machining, EDM Hole Drilling Service and Small Hole EDM Machining.

6. Heat Treatment Service

7. Surface Treatment Service

8. Assembly

9. Packing

10. Testing Report, QC Report